Introduction

STF BOILERS & HRSG designs and manufactures a wide range of steam generators in accordance with European Standards or ASME Code.

Our products include:

HEAT RECOVERY STEAM GENERATORS (“HRSG”)

INDUSTRIAL BOILERS

BIOMASS FIRED BOILER

WASTE-TO ENERGY and WASTE HEAT BOILERS

from small to large size units.

HEAT RECOVERY STEAM GENERATORS

Our Heat Recovery Steam Generators (HRSG) are designed in accordance with in-house technology, developed and standardized through many projects satisfactorily executed around the world with the most demanding clients.

Our references cover a very wide range of sizes, from HRSG behind small gas turbines of few MW up to the largest 500 MW units, firing gas or fuel oil.

We have a wide variety of designs that will be customized in order to meet your requirements:

- Horizontal or vertical exhaust gas path.

- Natural or assisted circulation.

- One, two or three pressure levels with or without reheating.

- Advanced steam parameters.

- Top supported heat exchange bundles.

- Pressure parts in loose harps or modular sections.

- Drum-type or once-through type HRSGs.

- Cold or hot casing design.

- Supplementary firing or fresh air firing system.

- Design for base load or cycling operation and fast start-up.

- Internal or external deaerator.

We build turn key boilers for green field or repowering projects, including, when requested, auxiliary systems, boiler housing, SCR deNOX systems etc.

Our Projects

Ibiritè (Brazil); Ponti sul Mincio (Italy); Porto Corsini (Italy); Tavazzano (Italy); Cassano d'Adda (Italy); Termini Imerese (Italy); Leinì (Italy); Gonyu (Hungary); Gebze (Turkey); Mittesburen (Germany).

- Ibirité (Brazil)

- Ponti sul Mincio (Italy)

- Porto Corsini (Italy)

- Porto Corsini (Italy)

- Tavazzano (Italy)

- Cassano d’Adda (Italy)

- Termini Imerese (Italy)

- Termini Imerese (Italy) 3D

- Leinì (Italy)

- Mittelsburen (Germany) 3D

- Gonyu (Hungary)

- Gebze (Turkey)

Harps & Modular sections

Our Projects

Jebel Ali (UAE); Laverà (France); Corinth (Greece); Aspropyrgos (Greece); Amilly (France); Kingisepp (Russia); Kima (Egypt).

- Jebel Ali (UAE)

- Jebel Ali (UAE)

- Jebel Ali (UAE)

- Jebel Ali (UAE)

- Laverà (France)

- Corinth (Greece)

- Aspropyrgos (Greece)

- Amilly (France)

- Inelectra_Venezuela

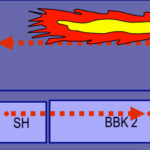

- Horizontal flue gas path pk boilers

- Rear wall heders

INDUSTRIAL BOILERS

STF BOILERS & HRSG supplies a full line of state-of-the art industrial boilers to meet the needs of a variety of industries, including petroleum refineries, petrochemical, chemical, oil & gas, metal, desalination plants, pulp and paper, textile and food industries, district heating plants and utilities.

We supply industrial boilers in accordance with two basic design configurations: horizontal flue gas path package boilers and vertical flue gas path boilers.

Our boilers are designed to get:

- Maximum efficiency;

- Extremely low levels of NOx and CO emissions to meet the most stringent requirements;

- Long term reliability;

- High turn-down ratio;

- High degree of automation.

Technical features common to both the types of boilers include:

- Two drum design;

- Large furnace dimensioning to ensure complete combustion and minimize emissions;

- Mono-wall fin tube construction;

- Low NOx burners and flue gas recirculation;

- High efficiency internals for steam drums;

- Minimum use of refractory.

Fuels: natural gas, light oil, heavy oil, refinery gas and low heating value gases.

Horizontal flue gas path package boilers

This type of industrial boilers is characterized by the horizontal flow of flue gas.

Starting from standardized models our package boilers are custom designed to suit the requirements and the needs of each client.

The steam production range goes from 10 t/h up to 250 t/h, temperature up to 510°C and pressure up to 100 Barg.

The superheaters are fully drainable.

They are designed for mono-block transportation and fast installation.

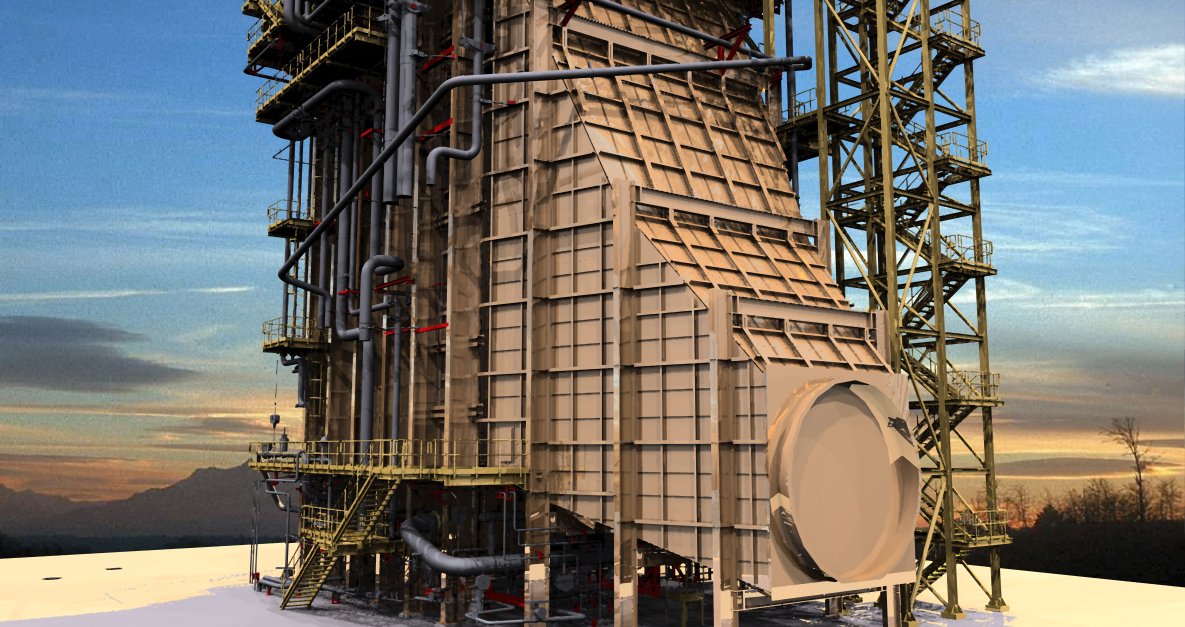

Vertical flue gas path boilers

This type of industrial boilers traditionally named “SD boilers” is characterized by the vertical flow of flue gas.

The design is based on standardized sections of the furnace and boiler bank, while the boiler width is defined to suit the design steam output. The design is then customised to meet the requirements and the needs of our clients.

The steam production range goes from 100 t/h up to 400 t/h, temperature up to 510°C and pressure up to 100 Barg.

The combustion system includes 4÷8 gas/oil burners.

The superheater can be fully drainable or non-drainable, convective or radiant type.

These boilers can be either shop, dock or field assembled as possible in accordance with transportation and erection constrains.

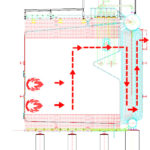

BIOMASS FIRED BOILERS and WASTE-to-ENERGY BOILERS

STF Boilers & HRSG supplies small-medium size biomass fired boilers and WTE boilers under a license to use the technology and know-how of Pensotti FCL.

Biomass fired boilers can utilise a wide range of biomass fuels including wood chips, saw dust, bark, wheat straw, rice husk, bagasse, grape and other agricultural residues etc.

WTE boilers can utilize municipal solid waste, refuse derived fuel, waste wood and waste gases. Depending on the type of fuel, its physical and chemical properties, we can utilize air cooled or water cooled reciprocating or vibrating combustion grates.

We supply also simple waste heat recovery plants from external plants.

Additional information

The boilers are drum type, natural circulation, normally with two or three vertical radiation passes.

The convection pass, in which the superheaters, evaporators, and economisers are located, may be horizontal or vertical.

In WTE boilers walls and superheaters sections are manufactured with Inconel cladding for corrosion protection.

- Nottingham (UK)

- Olevano-Biolevano (Italy)