Introduction

STF BOILERS & HRSG designs and manufactures a wide range of steam generators in accordance with European Standards or ASME Code.

Our products include:

HEAT RECOVERY STEAM GENERATORS (“HRSG”)

INDUSTRIAL BOILERS

BIOMASS FIRED BOILER

WASTE-TO ENERGY and WASTE HEAT BOILERS

from small to large size units.

Our Projects

Jebel Ali (UAE); Laverà (France); Corinth (Greece); Aspropyrgos (Greece); Amilly (France); Kingisepp (Russia); Kima (Egypt).

- Jebel Ali (UAE)

- Jebel Ali (UAE)

- Jebel Ali (UAE)

- Jebel Ali (UAE)

- Laverà (France)

- Corinth (Greece)

- Aspropyrgos (Greece)

- Amilly (France)

- Inelectra_Venezuela

- Horizontal flue gas path pk boilers

- Rear wall heders

INDUSTRIAL BOILERS

STF BOILERS & HRSG supplies a full line of state-of-the art industrial boilers to meet the needs of a variety of industries, including petroleum refineries, petrochemical, chemical, oil & gas, metal, desalination plants, pulp and paper, textile and food industries, district heating plants and utilities.

We supply industrial boilers in accordance with two basic design configurations: horizontal flue gas path package boilers and vertical flue gas path boilers.

Our boilers are designed to get:

- Maximum efficiency;

- Extremely low levels of NOx and CO emissions to meet the most stringent requirements;

- Long term reliability;

- High turn-down ratio;

- High degree of automation.

Technical features common to both the types of boilers include:

- Two drum design;

- Large furnace dimensioning to ensure complete combustion and minimize emissions;

- Mono-wall fin tube construction;

- Low NOx burners and flue gas recirculation;

- High efficiency internals for steam drums;

- Minimum use of refractory.

Fuels: natural gas, light oil, heavy oil, refinery gas and low heating value gases.

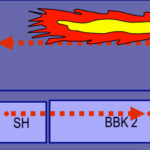

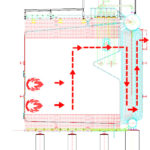

Horizontal flue gas path package boilers

This type of industrial boilers is characterized by the horizontal flow of flue gas.

Starting from standardized models our package boilers are custom designed to suit the requirements and the needs of each client.

The steam production range goes from 10 t/h up to 250 t/h, temperature up to 510°C and pressure up to 100 Barg.

The superheaters are fully drainable.

They are designed for mono-block transportation and fast installation.